PRÄZIPRESS and HEAVY PRÄZIPRESS

High precision reloading presses „Präzipress“

The Präzipress series stands out due to 3 main Features.

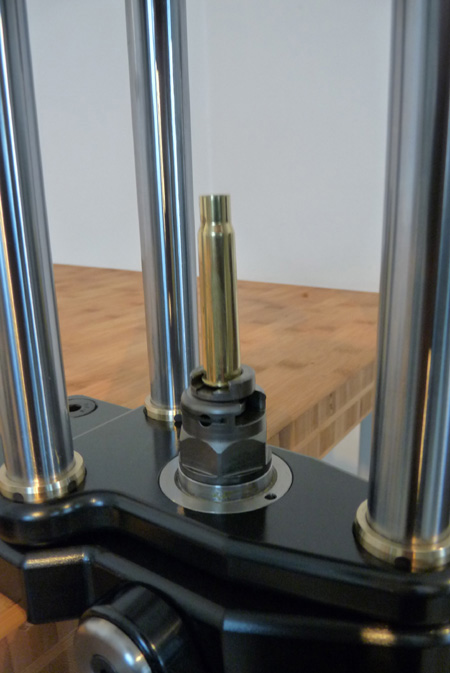

Accuracy

Lowest tolerances and high precision manufacturing ensure the highest accuracy between headplate und baseplate. There is only a minimum of play, which allows the sled to move smoothly.

Durability

All parts are made of carbon steel and more than sufficient dimensioned. The guiding pillars are hardened and run in brass bushings with solid lubricant embedded. Components, which contact other steel parts (dies, shell holders) are surface hardened and grinded.

Quality „Made in Germany“

The components for these presses are produced on modern CNC-machines in Germany. We make sure to use materials, tools and machines only, which correspond to our high standards of quality. There are no aluminium or cast iron parts, all surfaces are burnished and the edges rounded.

We offer 3 different versions:

Präzipress, Heavy Präzipress 120mm and Heavy Präzipress 140mm

PRÄZIPRESS

HEAVY PRÄZIPRESS 120mm

Heavy Präzipress 140mm

Precision press (stroke 105 mm)

Incl. 2 reducing sleeves

Incl. hook wrench

Incl. open-end wrench

Technical data “PRÄZIPRESS”

– Version 2 columns

– Lifting height 105 mm

– Mounting in the head plate 1 ¼ x 12 UNF , adapter to 7/8 x 14 UNF included

– Holder for standard sleeve holder

– 3 guiding pillars, with linear roller guides

– 120 mm stroke way

– headplate thread size 1 ½ x 12 UNF, inclusive adaptors to 1 ¼ x 12 UNF and 7/8 x 14 UNF

– comfortable reloading up to .408 Chey Tac or similar

– 3 guiding pillars

– 140 mm stroke way

– headplate thread size 1 ½ x 12 UNF,

– inclusive adaptors to 1 ¼ x 12 UNF and 7/8 x 14 UNF

– comfortable reloading up to .50 BMG